Stuart No. 1

This engine belongs to my daughter-in-law and it was built by her dad back in the early 1970s. He could never get it to go, so she brought it to me and asked me if I could fix it.

It was well and truly seized, not really surprising when it had remained idle for so many years.

So I set to, opened to top cylinder cover, lots of WD40 and a lot of rocking back and forth. Eventually it started to turn, but it was really reluctant to do so. I put some compressed air into it and it tried, but air seemed to be coming out all over the place.

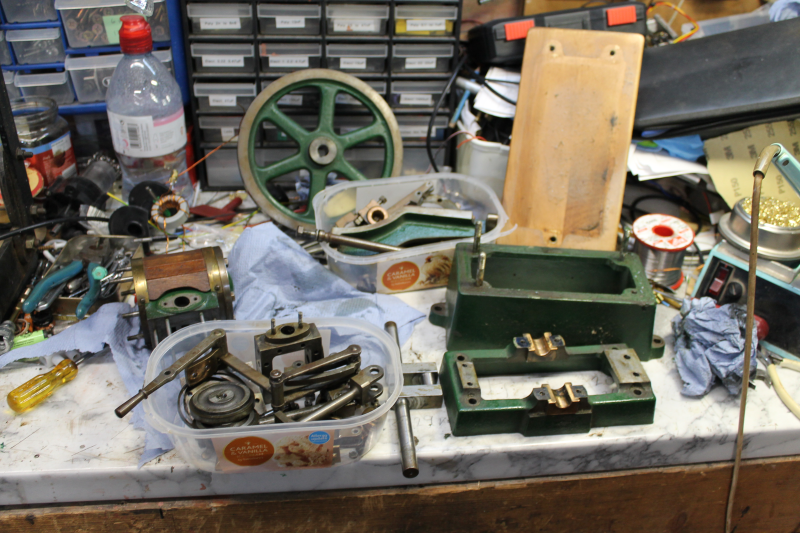

Nothing for it then, it had to be stripped down.

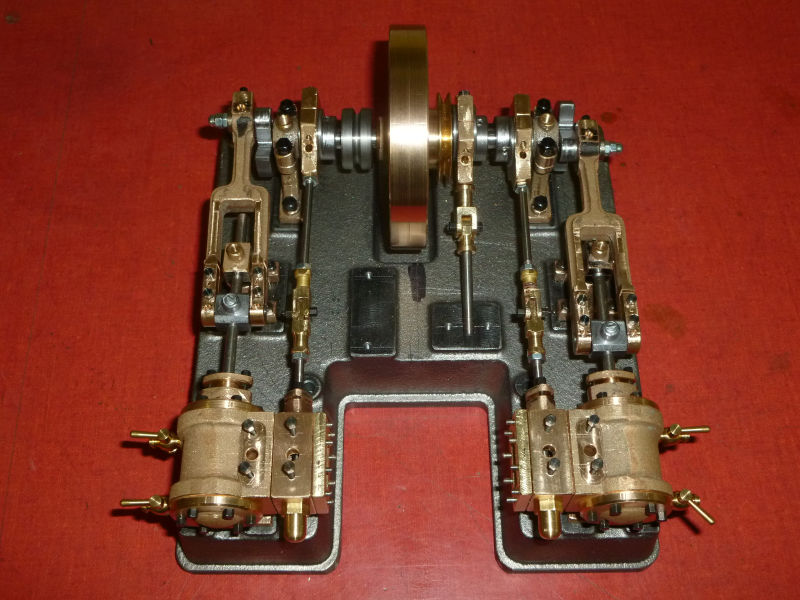

All those bits: I hope I can put it together again!.

So I started cleaning everything of all the old oil and grot and then realised why it wouldn't go. Nowhere was there any trace of gaskets or other sealing. No stuffing in the piston gland and the surfaces on the steamchest had to be seen to be believed!

Lots of work required.

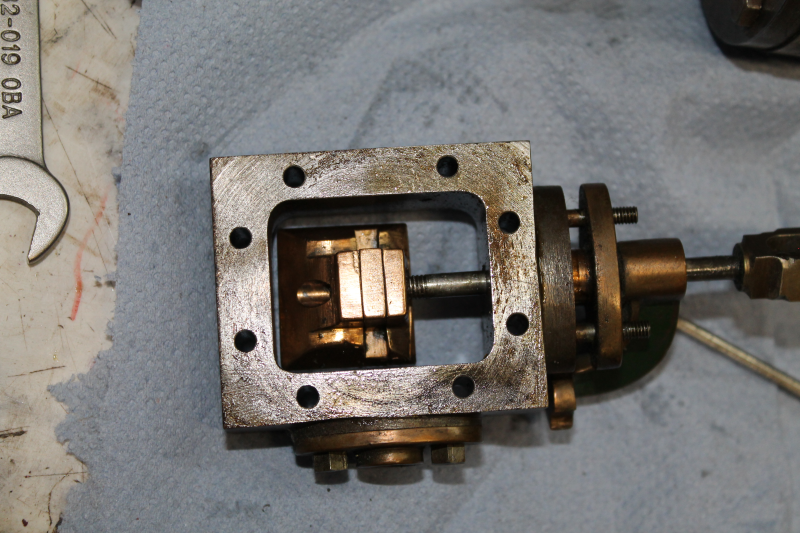

No sign of any packing at all.

Looks like it just came off the lathe.

So I cleaned it all up, made gaskets for the steamchest (and improved the mating surfaces), put "O" rings in the piston and valve rod glands and started to re-build.

Then I realised that, although all the parts had been made accurately to the drawings, they had never been 'fitted'. So, set to again and fit the parts properly, ensuring that they move where required.

After a couple of days fitting and building, it started to look like it might run.

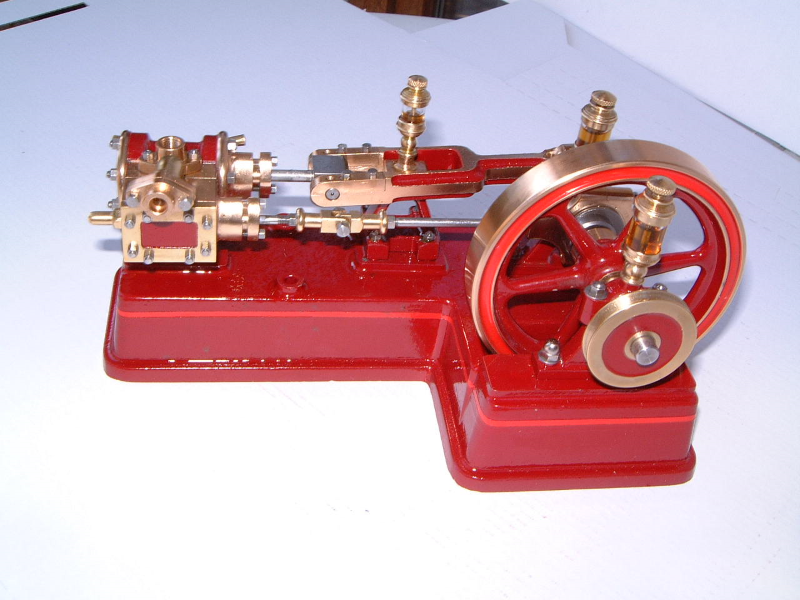

All built up again, but will it run?

Download Video:

Closed Format: "MP4"

Well, that's a relief! First time it's ever run and daughter-in-law is chuffed to bits.

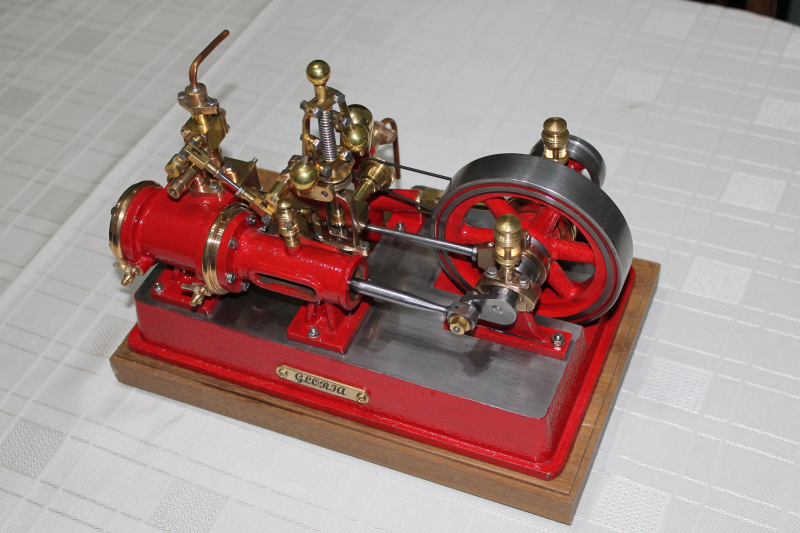

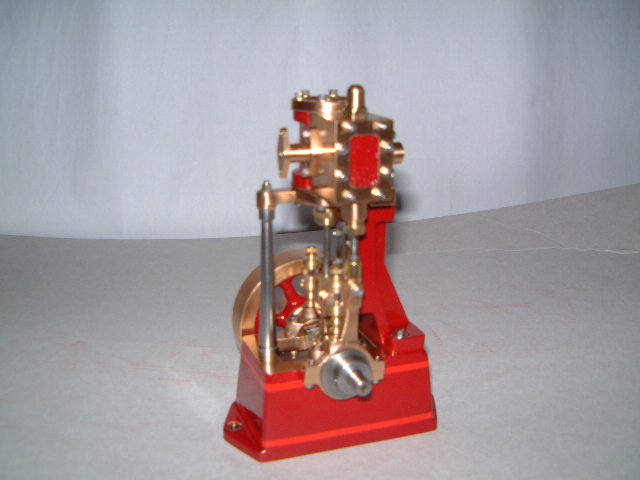

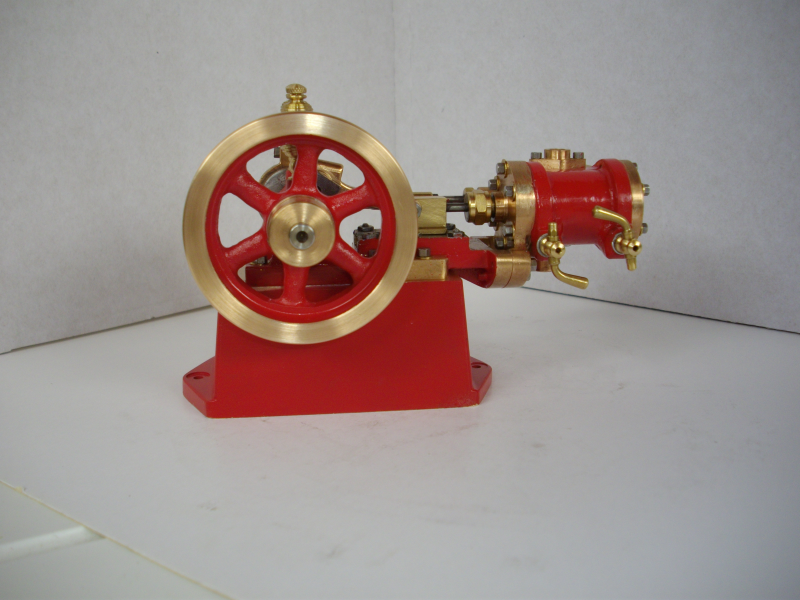

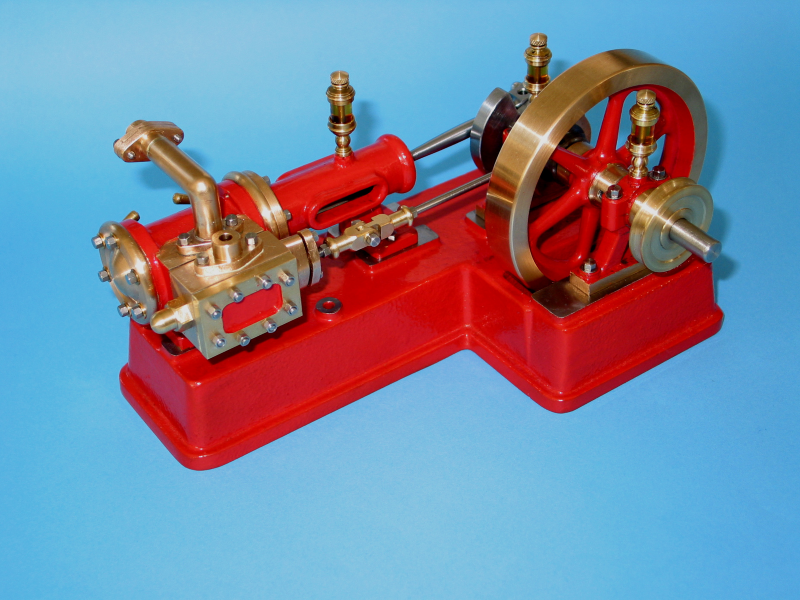

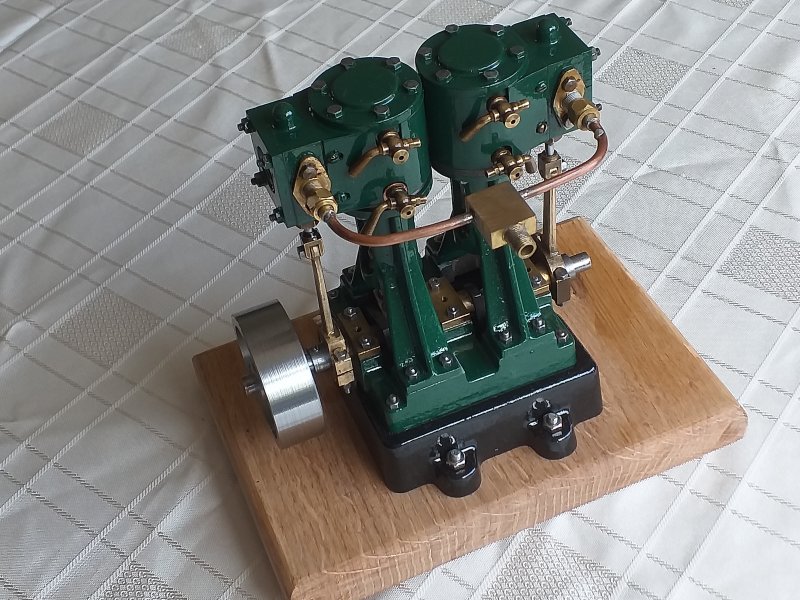

Stuart D10

Surely every model engineer has at some time built a Stuart steam engine.

Well, this is a typical example.

I was given a 'box of bits' by a friend at my model engineering club, as he was trying to make space in his workshop.

Turned out it was a Stuart Double 10 which had passed through several hands, each doing a bit of the build, so all I had to do was finish it off.

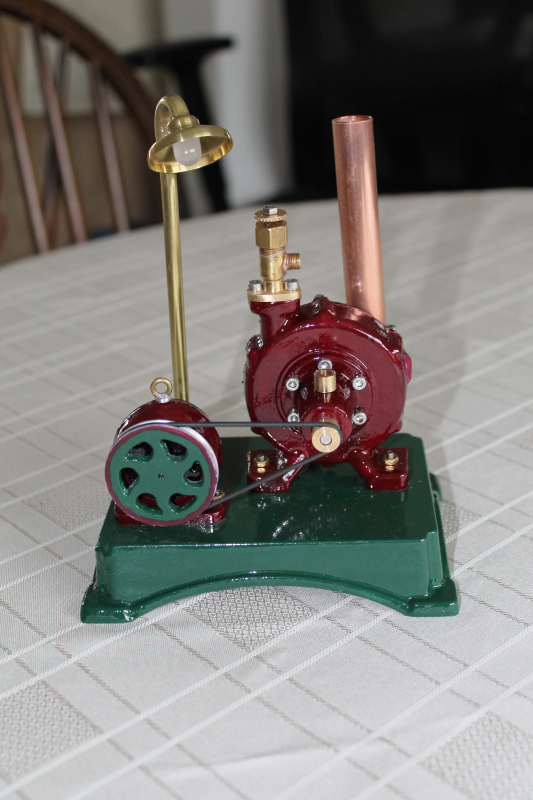

Turbine

<

This is more a novelty than a serious engine

It will light the lamp and it plays quite a tune!

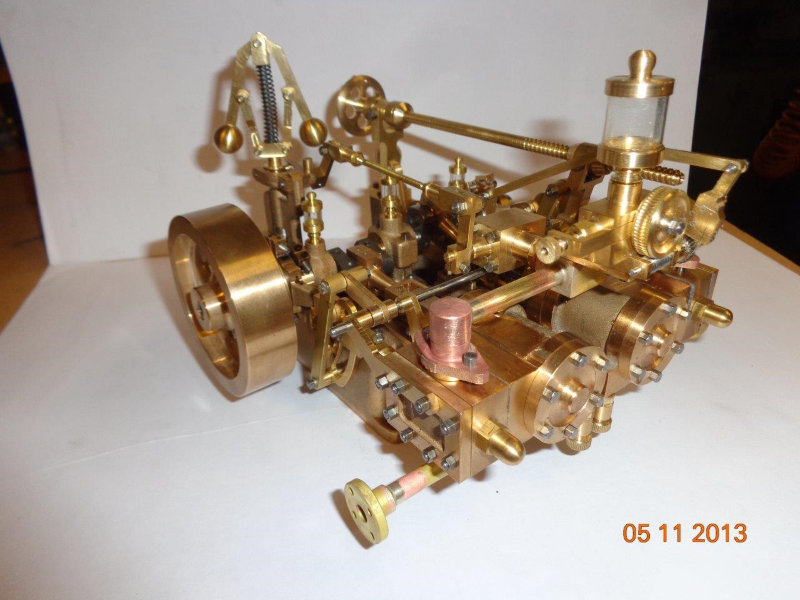

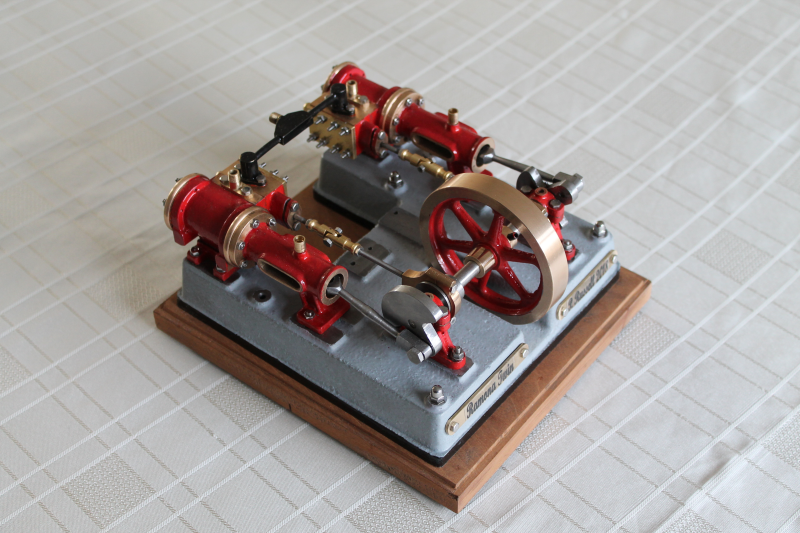

Stothert & Pitt Beam Engine circa 1851

The Stothert & Pitt Beam Engine was built for display at the Paris Exhibition and was intended for use as a general pupose power plant.

There is only one surviving engine and it is on display at the University of Bath.

The model ( in 1 / 12th scale ) was designed by Anthony Mount and is distibuted as a fairly comprehensive kit by Cotswold Heritage.

It is a high quality kit, many of the parts being laser cut. The "documentation" was a series of articles in "Engineering in Miniature"

written by Anthony Mount.

I spent 5 months building this engine in 2003. Not a particularly difficult build, but with my lack of experience, an excellent learning curve.

The engine runs well and has been exhibited at club events and also at the National Model Engineering Exhibition at Harrogate.

The nodding of the beam is mesmerising!